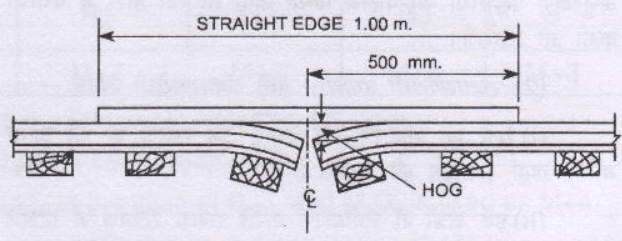

Hogged Rails

Due to the bettering action of wheels over the end of the rails, the rails get bent down and get deflected at the ends. These rails are called hogged rails.

This hogging of the rails at the ends is due to loose packing under the joints and/or loose fish plates. This defect causes rough riding. The following measures are taken to rectify the hogged rails

a. Cropping

In this method, the hogged ends are cut off and new holes are created in the rails for fixing the fish plate.

b. Replacing

In this method, the hogged rails are completely replaced by new rails. This method is very expensive.

C. Welding

In this method, the hogged rails are brought to the level by welding the deflected or worn-out ends.

D. De-hogging

In this method, the hogged ends of the rails are straightened by means of Jim screw or a de-hogging machine. This method is not so effective.

Buckling of Rails

Displacement of the track from its original position is known as buckling of rails.

Buckling of rails may take place due to the following reasons:

1. When the expansion gap is not sufficient.

2. When the bolt of fish plates are so tight that the rails are not allowed to expand.

3. Due to the presence of long welded rails on weak tracks.

Tilting of Rails

The art of placing the rails of a track at an inward slope of 1 in 20 is called tilting of rails. The main object of tilting of rails is to reduce the wear on inside edges of rails in a track. The required tilt is provided at rail seats in bearing plates, chairs and metal sleepers at the time of their casting.

The wooden sleepers, Which are used without bearing plates, are adzes to the required tilt of 1 in 20 at the rail seats.

Advantages of Tilting of Rails

1. The tilting of the rails enhances the life of both the sleepers and the rails.

2. The tilting of rails helps to hold the gauge in the correct position.

Read more: