The leakage in the pipe joints or any other points is tested by water test or air test.

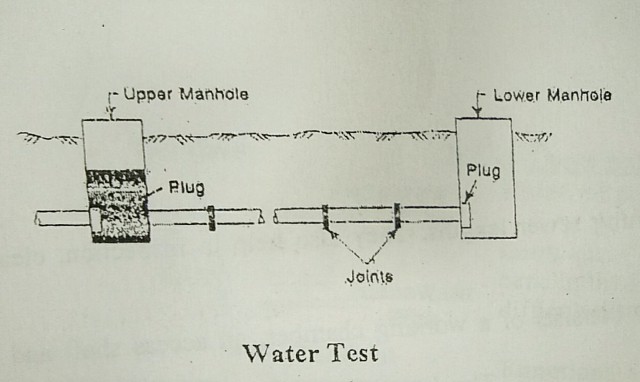

a) Water Test

This test is carried out between two manholes. The lower end of the sewer line is provided with a plug and the upper is kept open. In the manhole at the upper end, water is filled in and it is allowed to flow through the sewer line.

The depth of water in the upper manhole is maintained at about 150 cm. The water is allowed to stay in the sewer for a week. Then the sewer line is inspected to detect the leakage by observing any sweating. If the leakage is detected, it is rectified immediately.

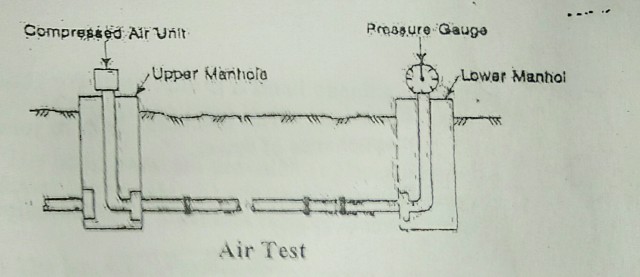

b) Air Test

This test is carried out for large diameter pipe. In this method, the pipe ends of both the manholes are plugged. An air compressor is connected to the plug of upper manhole and pressure gauge is attached with the plug of the lower manhole. The pressure is given in the pipeline by an air compressor and the amount of pressure is recorded in the pressure gauge.

It is left for a few hours. If the pressure drops below the permissible limit, then it is an indication of leakage. The exact point of leakage is found out by applying soap solution which will show bubbles at the point of leakage. If the leakage is detected, it is rectified immediately.

Read Also: