Types of Joints in Stone Masonry

Joints in stone masonry are provided to hold the stones tightly with each other. Following are the 10 types of joints in stone masonry.

- Square or Butt Joint.

- Lapped or Rebated Joint.

- Tongued and Grooved Joint.

- Table Joint.

- Dowelled Joint.

- Cramped Joint.

- Plugged Joint.

- Saddle Joint.

- Slate Joint.

- Rusticated Joint.

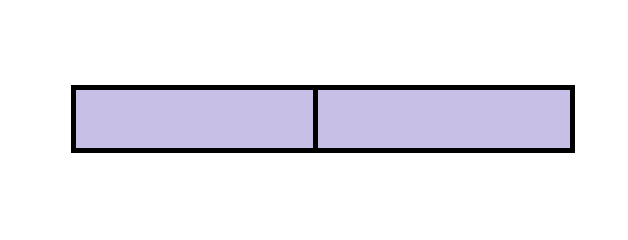

1. Square or Butt Joint

The butt joint is a very simple and easy and commonly used joint in ordinary stone masonry work. In this type of joint, two adjacent stones are placed in such a way that their square faces are abutted with each other.

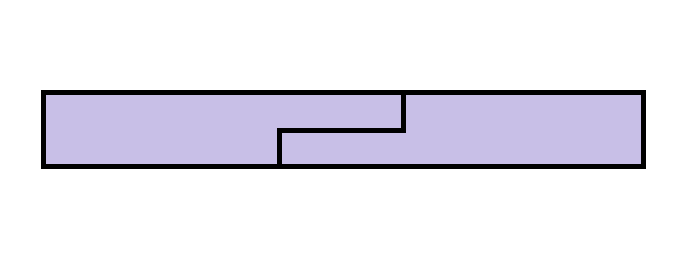

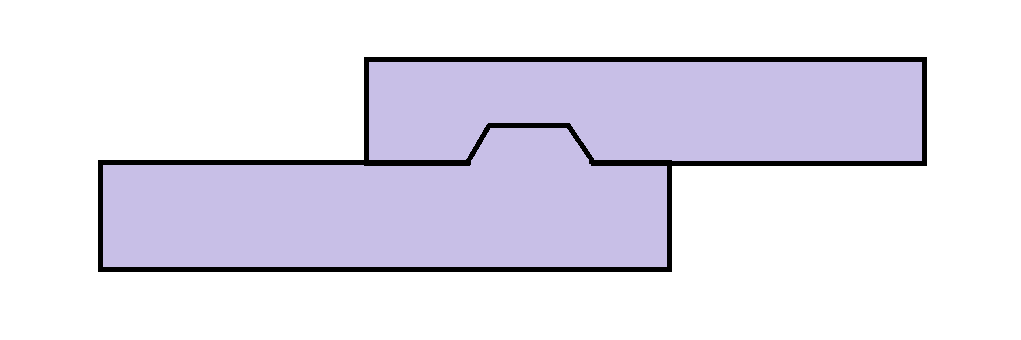

2. Lapped or Rebated Joint

The lapped joint is provided where the movement of stone pieces is to be prevented. In this case, rebates are provided to prevent the movements of stones. This joint is also known as a rebated joint. The length of the rebate should not be less than 70 mm. This joint is mostly used in arch work, coping on gables etc.

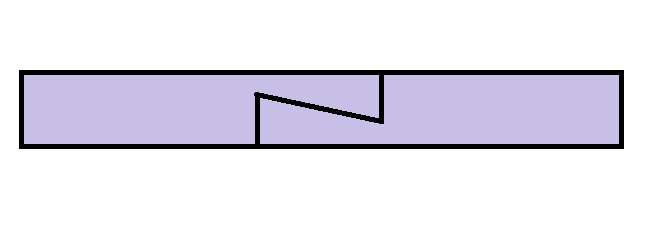

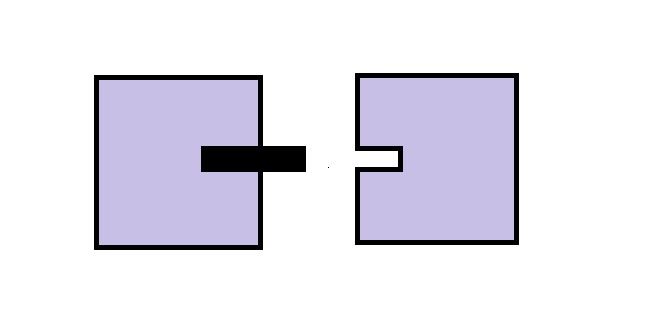

3. Tongued and Grooved Joint

In the case of the tongued and grooved joint, a projection is kept on one stone and a corresponding sinking is provided in the other stone as shown in the figure. This joint prevents sliding of one stone over the other, but they are more expensive than the above two types of joints, so they are less preferable. This joint is also known as a joggle joint.

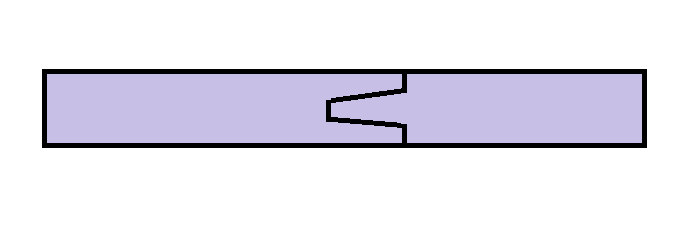

4. Table Joint

Table joint is suitable where the lateral pressure is high and need to prevent. In this case, to prevent the lateral pressure, a joggle is formed on the upper surface of the bed stone and a corresponding recess is formed on the bottom surface of the stone which laying above the bed stone, see figure. The recess of the upper stone is fastened on the joggle of the lower stone.

The depth of the projection should be about 4 cm, and the width of the projection should be one-third of the breadth of the stone. This joint is used where the lateral pressure is very high such as sea walls.

5. Dowelled Joint

In this joint, a hole is made into each stone. Then the dowels which are small pieces of hard stone, slate, gunmetal, bronze or brass are used for connecting these stones and secured with cement, see figure.

Usually, the thickness of the dowels are 2.5 cm, and they are around 10 cm to 15 cm long. This joint prevents unwanted displacement of stones. When the dowelled joint is provided for columns, is named as a bed plug.

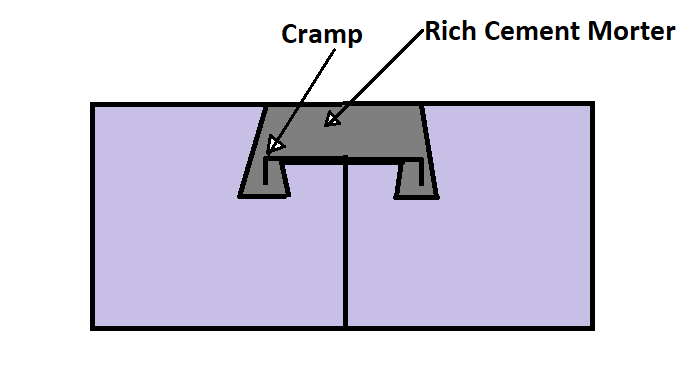

6. Cramped Joint

In cramped joint, the holes are made on the adjacent stones which will be as dovetail shape(which are shown in the figure). In this case, to connect these stones cramps are used instead of dowels.

The cramps are the piece of non-corrosive metal like gunmetal, copper etc. and their ends are turned down about a depth of 4cm to 5cm. The length of the cramps may vary from 200 mm to 300 mm. The width and thickness may vary from 2.5 cm to 5 cm and 0.5 cm to 1.0 cm respectively.

After placing the cramp into the proper position, the rest of the spaces are grouted with lead or cement mortar. The cramped is provided to prevent the joint to open out due to slippage of one of the stones.

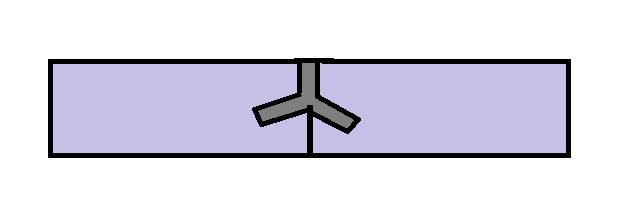

7. Plugged Joint

The plugged joint is same as a cramped joint. In this joint dovetail-shaped cuts are made in the sides of adjacent stones as shown in the figure. After arranging the stones in their proper position, molten lead is poured in the joint. This joint is mostly used for copings, cornices etc works.

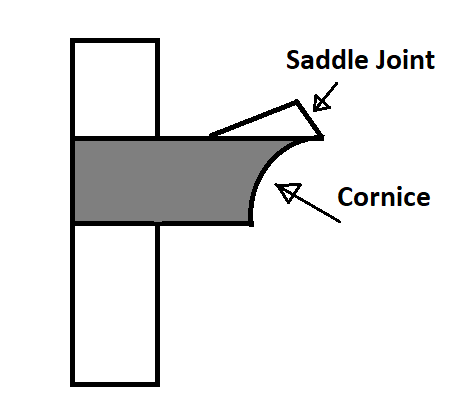

8. Saddle Joint

This type of joint is provided to protect the joints of the cornices and such other sloped surfaces. With the help of this arrangement, any water moving on the slope is diverted from the joints. This is also known as water joint.

9. Slate Joint

In this type of joint, grooves are made on the sides surface of the adjacent stones. A piece of slate is placed in between the corresponding groove of the adjacent stones.

10. Rusticated Joint

This type of joint mostly used in plinths or masonry in lower storeys of buildings. This joint may be different types such as channelled joint, vee joint, mould joint etc.

Read More: