Water Stops

Water stops are provided to prevent water from entering the structure through the joints. At the time of construction, they are set in place and later become a part of the structure.

What are the Reasons to Provide Water Stops in concrete Structure?

➤ To prevent the passage of water or other fluid.

➤ To increase the stability of the concrete structure.

➤ To prevent the concrete structure from decaying due to water.

➤ To prevent the chemical reaction.

➤ They can prevent the structure from the adverse effect of the environment.

➤ To prevent the dampness of the structure.

➤ At least, they prevent the cracking due to any of the above reasons.

As they prevent the passage of water, they are suitable in case of water-retaining structure, basement and underground construction.

Types Of Water Stops

Water stops can be divided into three types:

- Rubber water stop

- Metallic water stop

- Mastic type water stop

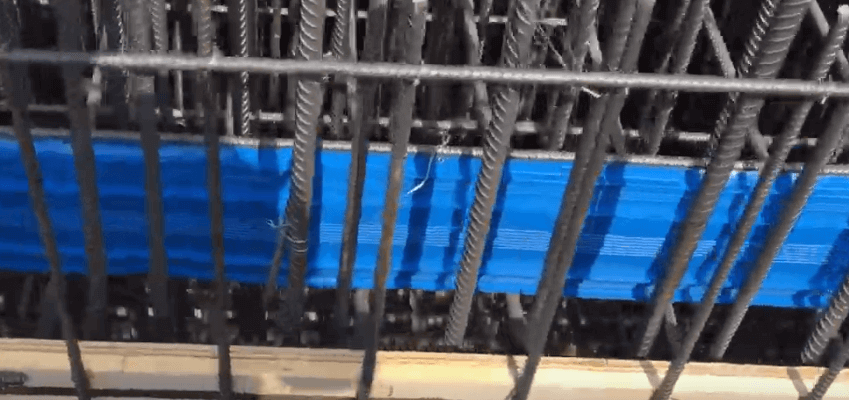

1. Rubber water stop

This water stop is made either from rubber or material having a lot of rubber. They should be accurately fixed in concrete to prevent them from being lifted by water pressure.

2. Metallic water stop

These types of water stops are made from steel, copper, zinc, etc. non-corrosive metal strips usually 14 to 16 gauge thick. On either side of the joint, the strip remains half embedded in concrete. The metal strip is bent in V or semi-circular shape at the joint.

3. Mastic Water stop

Mastic water stop is developed at the site of the joint by pouring mastic material into the joints. This form of water stop is ineffective in that case, where it is likely to be subjected to pressures and thrusts. So, it is not much more acceptable.

Read More:

Causes of Corrosion of Reinforcement in Concrete