What is a Lintel?

A lintel is a horizontal member, which is usually placed over the opening portion of a building like doors and windows. Lintel behaves just like a beam. It carries the load of the masonry work over the opening part and transfers all the load to the supporting walls. The lintels should have at least 150 mm bearing on the masonry on either side. Wright now, we will discuss the types of lintel used in building construction.

Different Types of Lintel

In this article, we will discuss about the different types of lintel used in building construction. lintel can only be classified according to the materials used in their construction. They are –

- Timber Lintel

- Stone Lintel

- Brick Lintel

- Reinforced Brick Lintel

- Steel Lintel

- R.C.C Lintel

- Thin Lintel

Note: Thin lintel is another type of lintel that is classified according to its thickness.

1. Timber lintel

Timber lintels were very common in use in the olden days when technology was not very advanced. Also at present time, some wooden lintels are used in buildings. But now it has become difficult and expensive due to the lack of timber availability.

It is also easily affected by white ants and other insects and that is why it is not preferred for modern construction. They are combustible and therefore not suggested for use in fireproof construction. The minimum depth of wooden lintels should be 7.5 cm. Timber lintels may be in a single piece or of built-up type.

Timber lintels should be made of sound and hardwood. The best and recommended wood for timber lintel is teak, sal, rosewood, etc.

Features:

They are flammable and therefore not suggested for use in fireproof constructions.

The depth of the timber lintels should not be less than 7.5 cm, and the width should be equal to the thickness of the opening.

Timber lintel can be of a single piece or of built-up type.

Without the proper seasoning, the timber is liable to decay as well as destroyed by fire.

If the timber lintel is used for large spans, it should be designed using flexural formula.

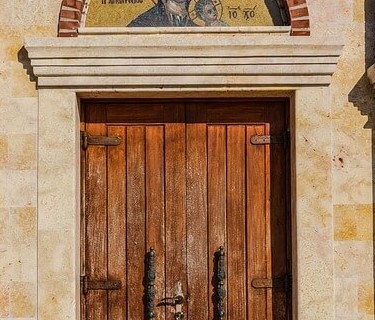

2. Stone Lintel

A Lintel made of stone is called a stone lintel. Stone lintels are very common in areas where the stone is widely available. They can be used as single pieces or in groups of several pieces. Stone lintels have good compressive strength but are poor in tensile strength and therefore they are not suitable for a long span. If it is used over a span of 1 m, then most of the load should be relieved by providing a relieving arch.

The thickness or depth of the stone lintel may be considered on the basis of the thumb rule that the thickness of the lintel should be 1 mm for every 10 mm span. We all know that the stone is not easy to handle and also required dressing work before it is used, and hence proves costly.

3. Brick Lintel

The brick lintel is another type of lintel which are mainly used for a short span, not more than 90 cm. Usually, first-class bricks are used to build brick lintels, which are either laid on end or on edge.

In the construction of a brick lintel, first of all, a temporary supporting timber structure is constructed. The thickness of the lintel should be multiple of brick course.

As I said before, for long spans and in case of heavy loads, this lintel should not be used. However, if this lintel is to be used for a large span, then reinforced brick lintel may be used. Read Also: Properties of First Class Brick

4. Reinforced Brick Lintel

Is brick lintel possible for long spans? Yes, possible if they are reinforced by a steel bar. When steel bars are provided with brick lintel is known as Reinforced Brick Lintel.

In this case, the bricks are arranged in such a way that 20 to 40 mm gaps are left, lengthwise, in the brick row. After that, Steel bars are inserted into this gap. And finally, empty places are filled with rich cement mortar or cement concrete.

In the case of a 20 mm gap, cement mortar is used to fill them. But, in the case of a 40 mm gap, concrete is used to fill this gap. The depth of the reinforced brick lintel should be a minimum of 100 mm. Read also: Reinforced brickwork and their advantages.

5. Steel lintel

Steel lintel is another type of lintel, consisting of angle irons or rolled steel joists. In the case of large spans and heavy loads, rolled steel joists are used. Whereas, for small spans and light loads, angle irons or steel channel sections are used.

Sometimes, steel joists are embedded in concrete to make it fir-proof, it is mostly used in the case of the shop front, bay window, etc. Angle or channel sections are generally preferred for small openings such as normal windows, bathroom windows, etc.

6. R.C.C lintel

R.C.C lintel or reinforced cement concrete lintel is one of the most usable lintels at present time. This is the lintel that has partially replaced all other types of lintels.

This lintel has fire-resistant properties as well as corrosion-resistant properties. It is durable, strong, and easy to construct. This type of lintel is more economical than any other type of lintel.

It can be used for any span and also for taking any loads. These lintels may be precast or cast in situ. In the case of a small span say about 1.5 m to 2 m precast lintels are used. In case of a large span, cast-in-situ lintels are used. Generally, M15(1:2:4) grade of concrete mix is used for casting of an R.C.C lintel.

The amount of reinforcement and depth required for an R.C.C. lintel depends on the span of the lintel, and the total load to be supported by the lintel.

7. Thin Lintel

The thin lintel is nothing but R.C.C. lintel having a thickness of around 75 to 100 mm. Above this R.C.C lintel, a brick or stone masonry is created and which acts as a part of this lintel.

How to calculate the total length of the lintel for an opening?

This is very simple to measure the total length of a lintel.

First, you have to know the bearing value.

The second is the length of the opening.

The total length of the lintel = Each end bearing value×2 + Total length of the opening.

Let’s take an example.

In the above picture, we can see that each side bearing value is 200 mm, and the total length of the opening is 600 mm.

The total length of the lintel = 200×2 + 600 = 1000 mm.

FAQs on Lintel

What type of lintel should I use?

If you ask me, what type of lintel should you use? Then I would suggest you to use RCC lintel and steel lintel. Because these two lintels are commonly used everywhere as they are easy to construct and durable.

What is the thickness of the lintel?

The thickness of a lintel depends on which type of lintel you want to use and the size of the opening and also the amount of load which is coming to the lintel. The thickness of lintels varies from 75 mm to 300 mm. But usually, 150 mm is preferred for residential as well as commercial buildings.

What is the width of a lintel?

The width of a lintel will be equal to the thickness of the opening. In other words, the width of a lintel should be the same as the thickness of the walḷ. Example: If the wall is 250 mm thick, then the width of the lintel will be 250 mm.

What size of rod is used for the lintel?

Generally, a 12 mm bar/road is preferred. The total number of bars will be 4. (From my experience point of view: you can use 10 mm bars as well for the lintel).

End bearing for lintels

The minimum end bearing for a lintel is 150 mm for each end. But some experts always recommended providing at least 200 mm bearing for each end.

Read Also:

Basic Parts of a Building Structure